More info

Select your bore, deck height, and rough or finish hone! If it says unavailable, they don't offer it.

RHS® – Delivering Power By Design™

Racing Head Service™ - the legendary innovator of airflow technology – offers the ultimate in cylinder head, engine block and intake manifold performance. Utilizing the resources of the industry leading COMP Performance Group™ engineering and development team and the most sophisticated engine technology in the performance aftermarket, RHS® has re-established itself as a leader in airflow design.

The Legacy of Innovation

Founded in 1967, Racing Head Service™ began exclusively as a manufacturer of racing cylinder heads. Over the years, RHS® grew into an integrated racing company, offering complete turn-key engines and race car parts via mail order. Always an innovator, RHS® was among the first to offer “crate engines” and mail order parts, establishing its reputation as a leader.

With innovative cylinder head designs and porting techniques, the company became a performance icon during the 1970’s and ’80s in both circle track and drag racing competition.

In 1976, the RHS® management team, recognizing the direct performance linkage between cylinder heads and camshafts, launched a new company – Competition Cams®. Throughout the '80s, RHS® and COMP Cams® became an amazing one-two punch for everything to do with racing. From their headquarters in Memphis, Tennessee, the two dominated NHRA and short track competition with their racing heads, valve train components and engines. Today, COMP Cams® has grown to be the dominant force in valve train technology and an established leader in the automotive aftermarket.

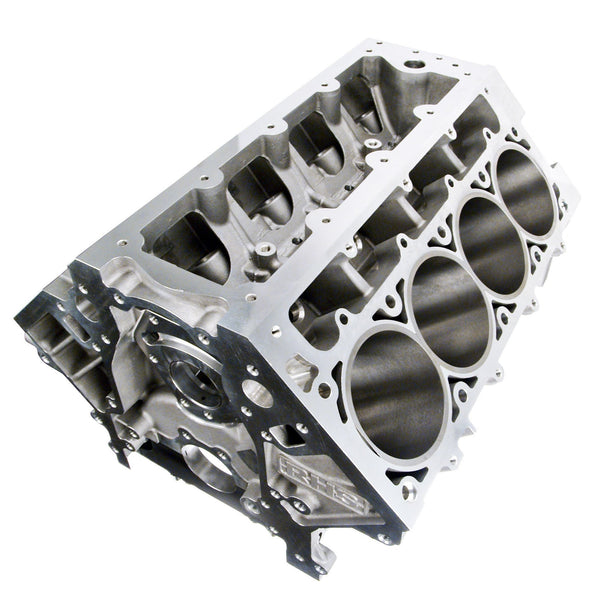

Engineers at RHS® have recently designed a high performance engine block for GM LS applications to meet the needs of race and street performance engine builders. To go beyond the limitations of other existing LS blocks, the new RHS® LS Race Block is available in both standard deck and tall deck height configurations. Additionally, this innovative block features a raised cam centerline and outboard priority main oiling to allow rod clearance for a 4.600” stroke and to minimize windage in the crankcase. And for quality control assurance, RHS® conducts a CT scan (similar to a medical CAT scan) on each block to ensure maximum casting precision and consistency. When you combine unmatched finishing quality with added clearance for increased stroke applications, precision computeraided design and extra surface material to allow custom machining, you get the new benchmark for LS horsepower, torque and durability.

RHS® – Delivering Power By Design™

Racing Head Service™ - the legendary innovator of airflow technology – offers the ultimate in cylinder head, engine block and intake manifold performance. Utilizing the resources of the industry leading COMP Performance Group™ engineering and development team and the most sophisticated engine technology in the performance aftermarket, RHS® has re-established itself as a leader in airflow design.

The Legacy of Innovation

Founded in 1967, Racing Head Service™ began exclusively as a manufacturer of racing cylinder heads. Over the years, RHS® grew into an integrated racing company, offering complete turn-key engines and race car parts via mail order. Always an innovator, RHS® was among the first to offer “crate engines” and mail order parts, establishing its reputation as a leader.

With innovative cylinder head designs and porting techniques, the company became a performance icon during the 1970’s and ’80s in both circle track and drag racing competition.

In 1976, the RHS® management team, recognizing the direct performance linkage between cylinder heads and camshafts, launched a new company – Competition Cams®. Throughout the '80s, RHS® and COMP Cams® became an amazing one-two punch for everything to do with racing. From their headquarters in Memphis, Tennessee, the two dominated NHRA and short track competition with their racing heads, valve train components and engines. Today, COMP Cams® has grown to be the dominant force in valve train technology and an established leader in the automotive aftermarket.

Engineers at RHS® have recently designed a high performance engine block for GM LS applications to meet the needs of race and street performance engine builders. To go beyond the limitations of other existing LS blocks, the new RHS® LS Race Block is available in both standard deck and tall deck height configurations. Additionally, this innovative block features a raised cam centerline and outboard priority main oiling to allow rod clearance for a 4.600” stroke and to minimize windage in the crankcase. And for quality control assurance, RHS® conducts a CT scan (similar to a medical CAT scan) on each block to ensure maximum casting precision and consistency. When you combine unmatched finishing quality with added clearance for increased stroke applications, precision computeraided design and extra surface material to allow custom machining, you get the new benchmark for LS horsepower, torque and durability.

Part Number 54906 Features:

Standard deck height (9.240)

5.87" cylinder sleeve length

3.900" Bore that has been finish honed and is ready for assembly

Block Specifications:

• Designed from heavy-duty A357-T6 aluminum material

• 4.125”-4.165” Siamese cast bore walls with press-in spun cast iron liner

• Available in standard (9.240”) & tall (9.750”) deck heights with beefy .750” deck thickness

• Both standard deck (5.67”/5.87”- same as LS7) & tall deck (5.94”/6.38”) cylinder liner lengths available

• Extra long liners for standard (5.87”) & tall (6.38”) decks

• “Long arm friendly” design – Accommodations for up to 4.6” stroke with standard rod pin diameters (2.100”) & oversized 60mm camshaft

• Designed for clearance – side oil galley moved outboard & engineered rod clearance come standard

• Raised cam centerline (.388”/9.86mm) to allow larger stroke; 2 extra links in the timing chain – Timing sets available from COMP Cams®

• Bay-to-bay breathing improved with increased side window area versus LSX & LS7

• Significantly increased windage passage area under bores & around caps over LS7/LSX engines

• 6 head bolt design with full water jacket around the cylinders (based on LS7 design)

• Extra large windows in valley for access to inboard “6th” head bolt

• Main Cap surface area maximized at mating surface & large fillets from cap to cross bolts for added strength

Valve Train Capabilities:

• Cam tunnel will accommodate stock through oversized 60mm roller bearing cams (includes cast-in lock screw pads)

• .842” lifters standard with material available for oversized lifter access (accepts 1.060” bushing for keyed lifters)

• In the standard deck, maximum pushrod angularity = Less than 2 degrees

• Includes Ampco 45 cam thrust plate and aluminum rear cover

• Lifter bosses designed to clear tie bar lifter

• Provisions for Gen III & Gen IV cam & knock sensors & valley covers

Superior Oiling:

• Dry sump friendly with provisions for more serious dry sump setups; includes big front & rear AN-12 side feeds

• Includes provision for piston oil squirters, cast-in & machined

• Priority main oiling, galley moved outboard for long stroke clearance

• Oil filter feed galley GM “dog bone” replaced with proprietary no restriction threaded plugs

Additional Features:

• Gen III/Gen IV compliant with race mounts for Gen I, Gen II, Gen III & Gen IV engines

• Optimized billet main caps & improved windage

• Rolled threads on all threaded holes for added strength

• Chilled main bearing bulkheads for added strength

• ARP main stud kit standard with enough material in castings to accommodate up to a ½” fastener

Standard deck height (9.240)

5.87" cylinder sleeve length

3.900" Bore that has been finish honed and is ready for assembly

Block Specifications:

• Designed from heavy-duty A357-T6 aluminum material

• 4.125”-4.165” Siamese cast bore walls with press-in spun cast iron liner

• Available in standard (9.240”) & tall (9.750”) deck heights with beefy .750” deck thickness

• Both standard deck (5.67”/5.87”- same as LS7) & tall deck (5.94”/6.38”) cylinder liner lengths available

• Extra long liners for standard (5.87”) & tall (6.38”) decks

• “Long arm friendly” design – Accommodations for up to 4.6” stroke with standard rod pin diameters (2.100”) & oversized 60mm camshaft

• Designed for clearance – side oil galley moved outboard & engineered rod clearance come standard

• Raised cam centerline (.388”/9.86mm) to allow larger stroke; 2 extra links in the timing chain – Timing sets available from COMP Cams®

• Bay-to-bay breathing improved with increased side window area versus LSX & LS7

• Significantly increased windage passage area under bores & around caps over LS7/LSX engines

• 6 head bolt design with full water jacket around the cylinders (based on LS7 design)

• Extra large windows in valley for access to inboard “6th” head bolt

• Main Cap surface area maximized at mating surface & large fillets from cap to cross bolts for added strength

Valve Train Capabilities:

• Cam tunnel will accommodate stock through oversized 60mm roller bearing cams (includes cast-in lock screw pads)

• .842” lifters standard with material available for oversized lifter access (accepts 1.060” bushing for keyed lifters)

• In the standard deck, maximum pushrod angularity = Less than 2 degrees

• Includes Ampco 45 cam thrust plate and aluminum rear cover

• Lifter bosses designed to clear tie bar lifter

• Provisions for Gen III & Gen IV cam & knock sensors & valley covers

Superior Oiling:

• Dry sump friendly with provisions for more serious dry sump setups; includes big front & rear AN-12 side feeds

• Includes provision for piston oil squirters, cast-in & machined

• Priority main oiling, galley moved outboard for long stroke clearance

• Oil filter feed galley GM “dog bone” replaced with proprietary no restriction threaded plugs

Additional Features:

• Gen III/Gen IV compliant with race mounts for Gen I, Gen II, Gen III & Gen IV engines

• Optimized billet main caps & improved windage

• Rolled threads on all threaded holes for added strength

• Chilled main bearing bulkheads for added strength

• ARP main stud kit standard with enough material in castings to accommodate up to a ½” fastener

![WEAPON-X: Wheel Spacers (Slip On) - 5x120 [CTS V gen 2/3, Camaro gen 5/6]](http://weaponxmotorsports.com/cdn/shop/products/44443_grande.jpg?v=1571441062)

![WEAPON-X: Wheel Spacers 15mm (Bolt on) - 5x120 [CTS V gen 2 or 3, Camaro gen 5 or 6]](http://weaponxmotorsports.com/cdn/shop/products/bolt_on_2d6a527f-6dcd-419f-95d5-5c1d99e60071_grande.jpg?v=1571441060)

![R1: Carbon Alloy Geomet Rotors [CTS V, Camaro ZL1, LSA]](http://weaponxmotorsports.com/cdn/shop/products/r1_geometry_e3d9a528-f0e7-4d34-bba0-5be6c8be9c9a_grande.jpg?v=1571441062)

![WEAPON-X: Wheel Spacers 15mm (Bolt on) - 5x114.3 [Corvette C6 C7]](http://weaponxmotorsports.com/cdn/shop/products/bolt_on_grande.jpg?v=1571441590)

![R1: Carbon Alloy Geomet Rotors [CTS V, Camaro ZL1, LSA]](http://weaponxmotorsports.com/cdn/shop/products/r1_geometry_ca7cec6c-6ae8-4b7d-b8ac-f8fdb57e86b5_grande.jpg?v=1571441774)

![Racing Brake: Karma Rotors (2pc) [CTS V gen 2, Camaro ZL1 gen 5]](http://weaponxmotorsports.com/cdn/shop/products/2141-2_grande.jpg?v=1571441146)

![Racing Brake: Karma Rotors (2pc) [CTS V gen 2, Camaro ZL1 gen 5]](http://weaponxmotorsports.com/cdn/shop/products/d216-07-381-01-2_small.jpg?v=1571441146)

![Racing Brake: Karma Rotors (2pc) [CTS V gen 2, Camaro ZL1 gen 5]](http://weaponxmotorsports.com/cdn/shop/products/FK1-10-2_small.jpg?v=1571441146)